High-Quality ASME Air Flow Nozzles

ASME nozzles are used for measuring pressure and flow through blower systems. They are either integrated into equipment or into air systems to help calibrate the proper flow of each system. Our nozzles are made to ASME standards and are typically in stock for quick lead times.

learn more

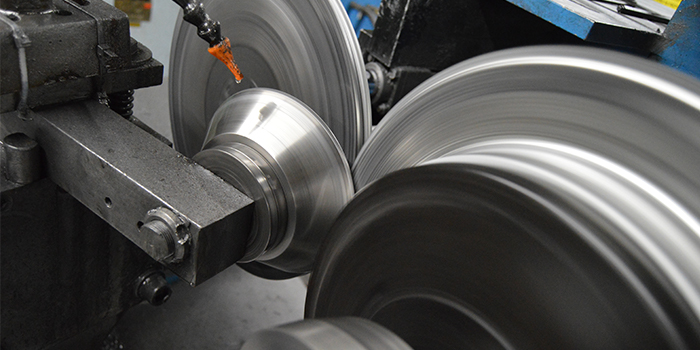

Metal Spinning

Water Jet Cutting

About Hy-Grade Metal Products Corp.

Hy-Grade Metal Products Corp is a custom manufacturer of metal spun parts. A wide variety of items can be made using metal spinning including antique restoration parts, ecclesiastical items, electrical plates and fixtures, lighting fixtures, and air/liquid movement parts. Metal spinning capabilities include the ability to handle large unusual concentric shapes. Hy-Grade has the capability to work from customer designs, ideas, sketches or prints for prototypes. There is no minimum order quantity. Small to medium production runs can easily be handled.

Hy-Grade Metal Products water jet table enables high precision cutting through a large variety of materials. Hard or soft materials are easily cut with incredible accuracy. CNC and nesting capabilities allow your extremely intricate parts to be manufactured in short lead times and low cost. Small quantity runs to thousands of units can be completed in short turn-around times.

Want to view more examples

of our capabilities?

Visit ourPhoto Gallery

Past Projects

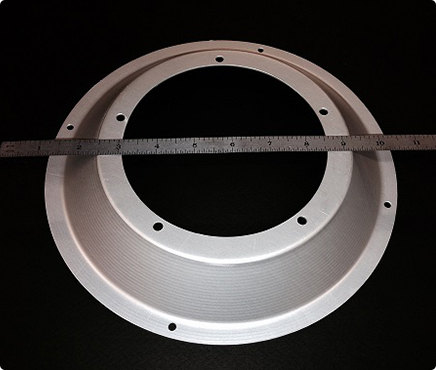

- Aluminum Offset Ring

Aluminum Offset Ring

This offset ring is used in the locomotive and light rail industry. Using 6061 aluminum, these parts were sheared, circled, spun and machined to tolerances of +/- .010”. After fabrication, parts are anodized to AAM32 C21-A31.

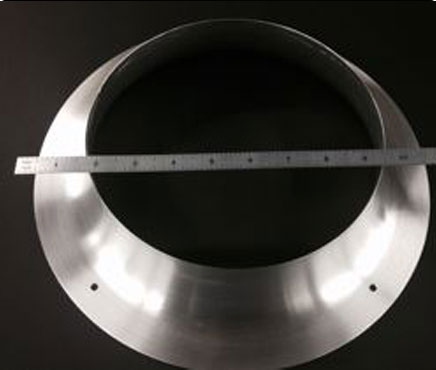

learn more - Aluminum Inlet Cone

Aluminum Inlet Cone

This inlet cone is used in the HVAC units of rail cars. It is essentially an air flow director for the units fan. Using 1100 aluminum, these part were sheared, circled, spun and machined to tolerances of as low as +/-.005”.

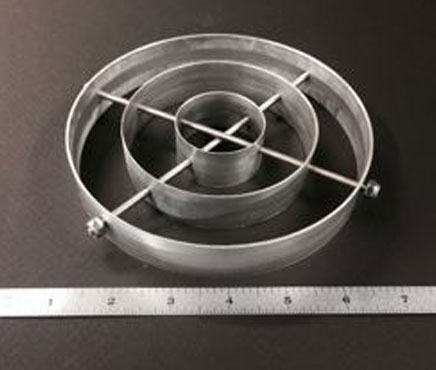

learn more - Glare Reducer Assembly

Glare Reducer Assembly

This glare reducer assembly is used in the lighting industry. It is an easily mountable unit that limits glare from lighting units, using 18 gauge 1100 aluminum, #8-32 aluminum threaded rod and #8-32 nuts with nylon inserts.

learn more - Condenser Fan Shroud

Condenser Fan Shroud

This condenser fan shroud is used in the air conditioning units of subway and rail cars. Using 14 gauge (.074”) cold rolled steel, these part were sheared, circled, spun and machined to tolerances of +/-.030”.

learn more - Flue Collector Collar

Flue Collector Collar

Flue collector collars are used to adapt boilers to duct work. We have made several different sizes ranging from 3” diameter to 10” diameter. Each of these items is made from 18 gauge gallivanted sheet.

learn more - ASME Air Flow Nozzles

ASME Air Flow Nozzles

ASME nozzles are used to measure air flow through blower systems. Hy-Grade has made several sizes and typically stock some for quick lead times. Each of these items is made from at least .065” aluminum sheet.

learn more